Non Destructive Testing(NDT)

Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.[1] The terms Nondestructive examination (NDE), Nondestructive inspection (NDI), and Nondestructive evaluation (NDE) are also commonly used to describe this technology.[2] Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. Common NDT methods include ultrasonic, magnetic-particle, liquid penetrant, radiographic, remote visual inspection (RVI), eddy-current testing,[1] and low coherence interferometry.[3][4] NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art.[1] Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography

Application

NDT is used in a variety of settings that covers a wide range of industrial activity, with new NDT methods and applications, being continuously developed. Non-destructive testing methods are routinely applied in industries where a failure of a component would cause significant hazard or economic loss, such as in transportation, pressure vessels, building structures, piping, and hoisting equipment.

NDT services offered by UIC:

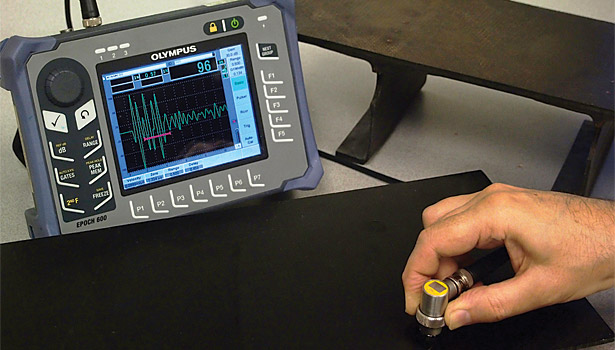

1.Ultrasonic Testing

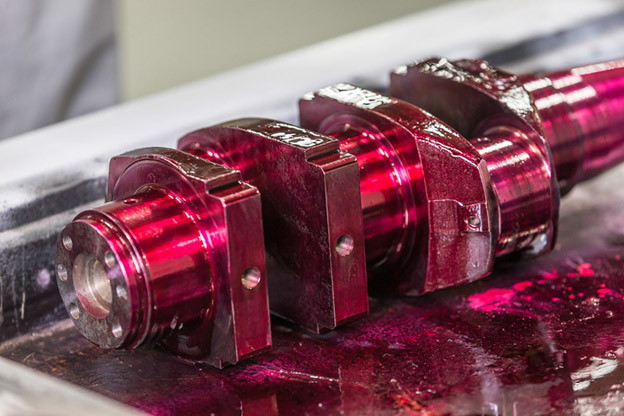

2.Magnetic-particle Testing

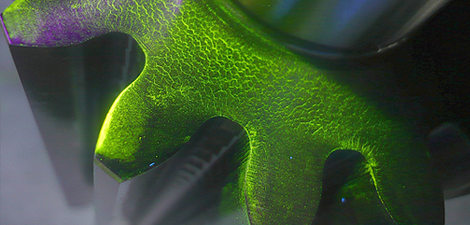

3.Liquid penetrant Testing

4.Radiographic Testing

5.Visual Testing

6.Advance Ultrasonic Testing

7.Tube inspection

Benifits of NDT testing

1. Accident prevention and to reduce costs .

2.To improve product reliability .

3.To determine acceptance to a given requirement .

NDT testing facilities at UIC, Jubail, KSA.

1. NDT testing equipment like mentioned below:

• MT yokes & chemical

• PT chemical

• UT machine

• RT source

• AUT machine

2. Experienced NDT inspector for carry out difficult configuration of welds.

3. Experienced in house ASNT NDT Level III and experts for providing techniques establishment, procedure preparation, approval and consultancy services

4. ASNT NDT Level III trainers for conducting in house or external NDT Level 2 training and certification courses on Ultrasonic testing and other NDT inspection methods. Read more about Ultrasonic Testing Personnel Certifications.

5. NDT inspectors qualified and certified to Level II as per ASNT recommended practice SNT-TC-1A is approved & also BINDT (British institute of nondestructive testing) approved Level-II according to ISO 9712:2012 for carry out inspection.